JINPENG Flat Knitting Machines

Our products range has also expanded from the early hand-driven flat knitting machines to the current automatic, computerized automatic and multi-functional flat knitting machines and tape knitting machines. Besides domestic markets, products are exported to a number of countries and regions from Asia, where they enjoy a high reputation due to their quality.

JP - 501 Specification | |

| MODEL | JP - 501 |

| GAUGE | 7G, 9G, 10G, 12G, 14G, 16G, 18G, optional |

| BED WIDTH | 52 inches optional |

| SPEED | maximum 1.2m/sec depending on knitting wide & knitting material |

| YARN FEEDER | Two side interchangable feeders, 6 colour |

| CARRIAGE | Single carriage system, single system, tuck knitting and plain knitting |

| STITCH DENSITY | 0~ 99 divisions by computer control |

| RACKING | 2 inches maximum |

| ROLLER | D/C motor control, 2 speed options |

| AUTO STOP | Yarn Break; knot; Yarn loose; reverse Rolling; Fabric Drop; Needle breal; Floating Knit; Motor Overload |

| DRIVER SYSTEM | The carrage is driven and controled by a JINPENG operating System |

| TOP TENTION | New Type Top Tention |

| LED LIGHT | Green : Working; Red: Error or stop |

| LAMP LIGHT | Locate inside power |

| POWER | 220v, single phs or 380v, 3phs optional |

| CONTROL SYSTEM | JINPENG designer Operating System |

| CONTROL LAUNGUAGE | English / Chinese |

| NET WEIGHT | 424kg according to inches |

JP - 502 Specification | |

| MODEL | JP - 502 |

| GAUGE | 7G, 9G, 10G, 12G, 14G, 16G, 18G, optional |

| BED WIDTH | 68,80,100,(inches) optional |

| SPEED | maximum 1.2m/sec depending on knitting wide & knitting material |

| YARN FEEDER | Two side interchangable feeder, main 6 colour |

| CAM SYSTEM | Double carriages, Single cam system; tuck knitting |

| STITCH DENSITY | 0~ 99 divisions by computer control |

| RACKING | 2 inches maximum |

| ROLLER | D/C motor control, two speed options |

| AUTO STOP | Yarn Break; knot; Yarn loose; reverse Rolling; Fabric Drop; Needle breal; Floating Knit; Motor Overload |

| DRIVER SYSTEM | The carrage is driven and controled by a JINPENG operating System |

| TOP TENTION | New Type Top Tention |

| LED LIGHT | Green : Working; Red: Error or stop |

| LAMP LIGHT | Locate inside power |

| POWER | 220v, single phs or 380v, 3phs optional |

| CONTROL SYSTEM | JINPENG designer Operating System |

| CONTROL LAUNGUAGE | English / Chinese |

| NET WEIGHT | 702kg/ 750kg/ 939kg according to inches |

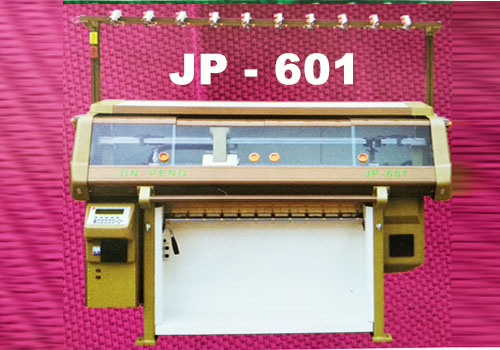

JP - 601 Specification | |

| MODEL | JP - 601 |

| GAUGE | 7G, 9G, 10G, 12G, 14G, 16G, 18G, optional |

| BED WIDTH | 42 (inches) optional |

| SPEED | maximum 1.2/sec depending on knitting wide & knitting material |

| YARN FEEDER | Two side interchangable feeders, 6 colour |

| CARRIAGE | Single carriage system, tuck knitting |

| JACK | Jacks on the front& rear bed, capable knitting square mini jacquard and line etc. |

| RACKING | 2 inches maximum |

| ROLLER | D/C motor control, two speed options |

| AUTO STOP | Yarn Break; knot; Yarn loose; reverse Rolling; Fabric Drop; Needle breal; Floating Knit; Motor Overload |

| DRIVER SYSTEM | The carrage is driven and controled by a JINPENG operating System |

| TOP TENTION | New Type Top Tention |

| LED LIGHT | Green : Working; Red: Error or stop |

| LAMP LIGHT | Locate inside power |

| POWER | 220v, single phs or 380v, 3phs optional |

| CONTROL SYSTEM | JINPENG designer Operating System |

| CONTROL LAUNGUAGE | English / Chinese |

| NET WEIGHT | 469kg according to inches |

JP - 602 Specification | |

| MODEL | JP - 602 |

| GAUGE | 7G, 9G, 10G, 12G, 14G, 16G, 18G, optional |

| BED WIDTH | 60, 80 (inches) optional |

| SPEED | maximum 1.2/sec depending on knitting wide & knitting material |

| YARN FEEDER | Two side interchangable feeders, 6 colour |

| CARRIAGE | Single carriage system, tuck knitting |

| JACK | Jacks on the front& rear bed, capable knitting square mini jacquard and line etc. |

| STITCH DENSITY | 0~ 99 divisions by computer control |

| RACKING | 2 inches maximum |

| ROLLER | D/C motor control, two speed options |

| AUTO STOP | Yarn Break; knot; Yarn loose; reverse Rolling; Fabric Drop; Needle breal; Floating Knit; Motor Overload |

| DRIVER SYSTEM | The carrage is driven and controled by a JINPENG operating System |

| TOP TENTION | New Type Top Tention |

| LED LIGHT | Green : Working; Red: Error or stop |

| LAMP LIGHT | Locate inside power |

| POWER | 220v, single phs or 380v, 3phs optional |

| CONTROL SYSTEM | JINPENG designer Operating System |

| CONTROL LAUNGUAGE | English / Chinese |

| NET WEIGHT | 694kg/ 793kg according to inches |

JP - 611 A Specification | |

| MODEL | JP - 611A |

| GAUGE | 9G, 12G, 14G, 16G |

| BED WIDTH | 42 (inches) |

| SPEED | maximum 1.5m/sec according to material & knitting structure |

| YARN FEEDER | 6 colour |

| CARRIAGE | Single carriage system |

| JACK | with jack can do semi jacquard |

| LYCRA SYSTEM | with Lycra cam system, can do high needle tuck, low needle tuck or all tuck |

| STITCH | From level 1-99 option |

| RACKING | Servo control maximum 2 inches, racking 1 or half needle in any problem |

| TAKE DOWN | From 1-9 level option |

| EMERGENCY STOP | Yarn Break; knot; Yarn loose; Yarn Drop; Fabric roll back, float tuck, needle broken, emergency stop, 0 position error, Motor Overload |

| LED LIGHT | Green : Working; Red: Error Yellow:normal stop |

| POWER | 220v or 380v |

| CONTROL SYSTEM | JINPENG 2016 System, Touch screen |

| CONTROL LAUNGUAGE | English / Chinese |

| NET WEIGHT | 510kgs |

JP - 711 Specification | |

| MODEL | JP - 711 |

| GAUGE | 12G, 14G, 16G, 18G |

| KNITTING WIDTH | 52, 80 (inches) |

| SPEED | maximum 1.2m/sec Knitting speed varies according to gauge and knitting condition, 32 sections speed option. Controlled by Servo motor with 0~100 level density adjustable. |

| OPERATIONAL KNITTING SYSTEM | Single carriage single system or double carriage single system |

| KNITTING FUNCTION | Full Jacquard |

| YARN CARRIERS | 6 yarn carriers on both side of carrier rails, capable to stop at any position |

| STITCH DENSITY | Controlled by step motor, 32 section density option, adjustable from 0-560 levels |

| NEEDLE SELECTION | Solenoid controlled needle selection for full jacquard |

| RACKING | Controlled by Serve motor.1-7 pitch and precision adjust function. |

| NEEDLE BED | Segment/ Common needle bed option |

| TAKE DOWN ROLLER | Controlled by step motor with 36 section of pull power. Each section of pullpower is adjustable from 0-100 levels. |

| STOP MOTION | Yarn Break; large knot; Fabric Drop; needle break, rewind, motor error, program error etc. |

| OPERATION LAMP | Green : normal operation ; Yellow:normal stop; Red: abnormal stop |

| CONTROLLING SYSTEM | 7 inches LCD industrial computer control. Touch interface showing running fingures and easy to change controlling program. USB sticker memory system. |

| POWER | 220v / 380v optional, memory recover function on power-off |

| VOLUME | 2425*1870*840mm |

| NET WEIGHT | 670kgs |

JP - 811 Specification | |

| MODEL | JP - 811 |

| OPERATING KNITTING WIDTH | 52 inches |

| KNITTING SPEED | maximum 1.2m/sec Knitting speed varies according to gauge and knitting condition, 36 sections speed option. Controlled by Servo motor with 0~100 level density adjustable. |

| OPERATIONAL KNITTING SYSTEM | Single carriage with single system |

| KNITTING FUNCTION | Front and back transfer independent from carriage direction, Tuck, Pointelle, Intarsia, Jaquard, Shaping |

| YARN CARRIERS | 6 yarn carriers on both side of 3 carrier rails, capable to stop at any position |

| STITCH DENSITY | Controlled by step motor, 36 section density option, adjustable from 0-800 levels |

| NEEDLE SELECTION | Solenoid controlled needle selection for full jacquard |

| RACKING | AC Controlled by AC Serve motor.1-7 pitch and precision adjust function. |

| NEEDLE BED | Segment/ Common needle bed option |

| TAKE DOWN ROLLER | Controlled by step motor with 36 section of pull power. Each section of pullpower is adjustable from 0-100 levels. |

| STOP MOTION | Yarn Break; large knot; Fabric Drop; needle break, rewind, motor error, program error etc. |

| OPERATION LAMP | Green : normal operation ; Yellow: Normal stop; Red: Abnormal stop |

| CONTROLLING SYSTEM | 7 inches LCD industrial computer control. Touch interface showing running fingures and easy to change controlling program. USB sticker memory system. |

| POWER | 220v / 380v optional, memory recover function on power-off |

| VOLUME | 2425*1870*840mm |

| NET WEIGHT | 650kgs |